In the ever-evolving world of technology, a new era of automation is upon us, driven by the fascinating rise of autonomous mobile robots (AMRs). Just as the Industrial Revolution transformed the manufacturing landscape, these intelligent machines are revolutionizing modern warehouses and transportation systems. With their ability to navigate and perform tasks independently, AMRs are reshaping how we view robotics and automation in our daily lives. Today, we delve into the intricate world of AMRs, their core applications, and the pivotal role they play in enhancing efficiency and productivity across various sectors.

The Core of AMR Technology

At the heart of autonomous mobile robots lies a sophisticated blend of software, sensors, and innovative engineering. These systems are designed to understand and interpret their environments, allowing them to execute tasks with minimal human input. An AMR’s navigation capabilities stem from its advanced sensors, such as LiDAR, cameras, and ultrasonic devices, which work in tandem to map out surroundings and avoid obstacles.

Incorporating artificial intelligence (AI) and machine learning algorithms, AMRs continuously adapt to changing environments, learning from each interaction to optimize their performance. As a result, these robots can seamlessly integrate into transport and logistics operations, facilitating a dynamic workflow that enhances overall productivity.

The real power of AMRs lies in their ability to operate autonomously. Unlike traditional automated guided vehicles (AGVs), which rely on predefined paths, AMRs can make real-time decisions based on sensor data. This level of autonomy not only increases flexibility but also minimizes downtime, creating a more efficient system tailored to specific operational needs.

Applications of AMRs in Modern Logistics

Warehouses and distribution centers serve as the backbone of the global supply chain, and the introduction of AMRs has brought about transformative change in these environments. Traditionally, human operators were responsible for transporting goods across vast spaces, often resulting in time-consuming and physically demanding work.

Enter the AMR—a modern solution that revolutionizes the way goods are handled and moved. These robots efficiently execute a wide range of tasks, from picking and packing to loading and unloading. By assuming these roles, AMRs alleviate the burden on human workers, allowing them to focus on more strategic and decision-making responsibilities.

Beyond the warehouse, AMRs are finding applications in healthcare, retail, and manufacturing sectors. In hospitals, these robots transport medical supplies and equipment, optimizing time for healthcare professionals. Similarly, in retail, they assist in inventory management by autonomously moving products and ensuring shelves are stocked effectively.

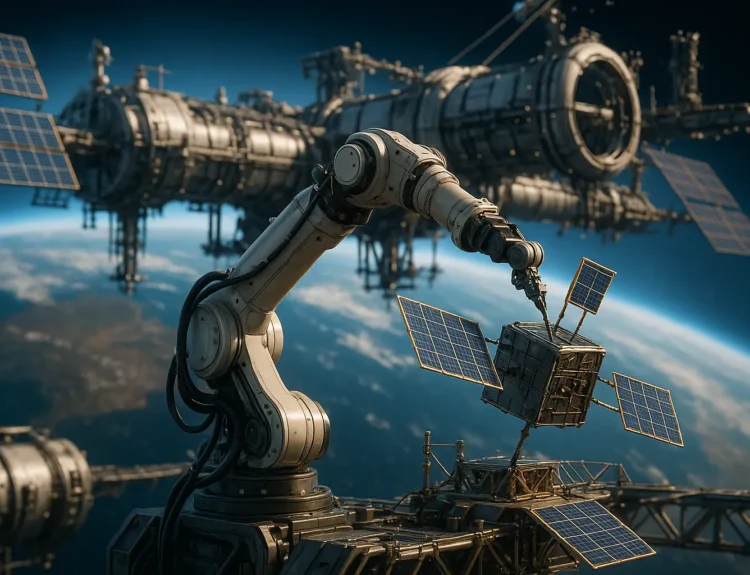

As we embrace this new wave of automation, it’s clear that AMRs are not just a fleeting trend but a pivotal technology that enhances efficiency and accuracy across industries. {image_content}

Navigating the Challenges and Solutions

While the potential of AMRs is vast, the journey towards widespread adoption is not without challenges. One of the foremost hurdles is ensuring reliable navigation in dynamic environments. AMRs must constantly interpret data from their surroundings, adjusting their paths accordingly. This requires robust software and precise sensor integration to ensure the robot can function safely and efficiently.

To address these challenges, developers are innovating novel solutions, including enhanced machine learning algorithms and real-time mapping techniques. The integration of cloud-based systems allows AMRs to access vast databases of spatial information, ensuring seamless navigation even in complex scenarios.

Another consideration is the integration of AMRs with existing infrastructure. Many facilities were not initially designed with robotic systems in mind, necessitating retrofitting or adaptation. Collaborative efforts between businesses and technology providers are essential to tailor solutions that meet specific operational requirements.

Despite these hurdles, the value proposition of AMRs is undeniable. By providing automation with minimal human intervention, they contribute to reducing operational costs, enhancing safety, and increasing productivity. As AMRs continue to evolve, they promise to redefine what’s possible in the realm of autonomous systems.

The Future of Autonomous Mobile Robots

As we look ahead, the future of AMRs is brimming with potential. The continuous advancements in robotics and technology promise to push the boundaries of what these machines can achieve. With ongoing research and development, we foresee a world where AMRs become an integral part of everyday operations, far beyond the confines of warehouses and industrial facilities.

Emerging trends point towards increased collaboration between AMRs and humans, fostering a synergistic relationship that maximizes efficiency. As these robots become more adept at understanding human cues and working in unison, the possibilities for enhanced operational processes are endless.

Moreover, the integration of sustainable practices is set to play a crucial role in the evolution of AMRs. By prioritizing energy-efficient designs and promoting eco-friendly operations, we can ensure that the adoption of this technology aligns with global environmental goals.

In conclusion, autonomous mobile robots stand as a testament to human ingenuity and the limitless potential of modern technology. As we continue to explore the vast opportunities they present, it’s clear that AMRs will play a pivotal role in shaping the future of automation and productivity.

The dawn of autonomous mobile robots marks an exciting chapter in the saga of robotics and automation. As we’ve explored, these innovative machines are more than just technological marvels; they are powerful enablers of efficiency, flexibility, and sustainability. By seamlessly integrating into diverse environments, AMRs are redefining the possibilities within transport, logistics, and beyond.

As we embrace this transformative technology, the future appears brighter than ever. With continued advancements and innovations, the potential applications for AMRs are boundless, setting the stage for a world where automation and human ingenuity coexist harmoniously. Together, we can leap into a future where autonomous systems lead the charge towards a more connected, efficient, and sustainable world.

FAQ

What exactly are autonomous mobile robots?

Autonomous mobile robots (AMRs) are machines designed to perform tasks without direct human intervention. They navigate and operate in various environments using sensors, cameras, and algorithms to make decisions and adapt to changing circumstances.

How do autonomous mobile robots navigate their surroundings?

AMRs utilize a combination of technologies such as LIDAR, cameras, and GPS to map and understand their environment. This technology allows them to detect obstacles, plan routes, and move efficiently from one location to another.

What industries primarily benefit from using autonomous mobile robots?

A variety of sectors benefit from AMRs, including manufacturing, logistics, healthcare, and agriculture. In these fields, robots are used for tasks such as material handling, inventory management, patient transport, and crop monitoring.

What are the main advantages of implementing autonomous mobile robots?

AMRs enhance efficiency, reduce labor costs, and improve safety by handling repetitive or dangerous tasks. They also offer flexibility, as they can be reprogrammed and redeployed quickly to accommodate different tasks or changes in the work environment.

How do autonomous mobile robots differ from traditional robots?

Unlike traditional robots, which are often stationary and require pre-set programming, AMRs are equipped with advanced sensors and AI capabilities. This enables them to adapt to dynamic environments, make real-time decisions, and move independently without relying on fixed infrastructure.